A Polymer Process Engineering & Training Company Home of the CRD Mixing Screws

|

|---|

During the compounding or mixing of polymers existing

mixers rely heavily on shear-type flows. It is well known that these type

of flows are prohibitive in their ability to create dispersive mixing, especially

at large viscosity ratios. Further, at large shear rates material temperature

and degradation issues arise. The Elongational Pin Mixer (EPM) – patent pending

– has been designed to overcome these problems by creating strong elongational

flows.

During the compounding or mixing of polymers existing

mixers rely heavily on shear-type flows. It is well known that these type

of flows are prohibitive in their ability to create dispersive mixing, especially

at large viscosity ratios. Further, at large shear rates material temperature

and degradation issues arise. The Elongational Pin Mixer (EPM) – patent pending

– has been designed to overcome these problems by creating strong elongational

flows.

These flows are able to disperse at very large viscosity ratios and are more

efficient than shear flows – giving reduced viscous dissipation and melt

temperatures.

To obtain a fine level of dispersion, it is generally necessary for the agglomerates

or droplets to be broken down several times, which means that the material

must pass through a high stress region (HSR) multiple times. The EPM was

designed to assure that all material experiences a similar level of mixing

and can guarantee multiple passes through the HSR by incorporating multiple

rings in series.

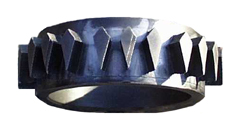

The elongational pin mixing ring shown here is easily added to the mixing section of the extruder or injection molding screw to give enhanced dispersive and distributive mixing.

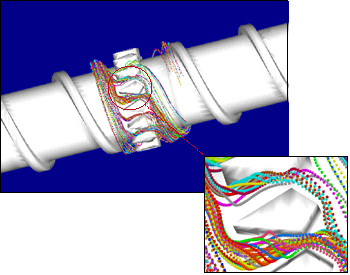

The EPM has also been designed to create an optimal level of distributive mixing by severely modifying the streamlines as they pass through the mixer. In a relatively shot distance the EPM increases the spatial distance of the material. The figure below demonstrates this phenomena using results from the boundary element simulation program BEMflow. Here, an “agglomerate” made up of many particles “breaks-up” very quickly with the distance between particles increasing rapidly.

Advantages of the EPM Mixer

These figures show particle tracking predicted with

BEMflow. Here, the large distributive mixing effect can be seen by the fanning

out of the particles. The close-up view shows the twisting cross-flow and

the elongational effect due to the acceleration of the particles as they

move through the wedges.

These figures show particle tracking predicted with

BEMflow. Here, the large distributive mixing effect can be seen by the fanning

out of the particles. The close-up view shows the twisting cross-flow and

the elongational effect due to the acceleration of the particles as they

move through the wedges.

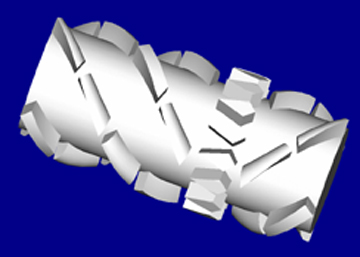

The elongatonal pin mixing ring (EPM) can be used as a stand alone mixing device or with existing mixing sections. This figure shows the EPM with the CRD mixing section to provide an even higher level of dispersive and distributive mixing. This combination has been used on single and twin screw extruders of various sizes from 2" to 12" diameter.